Categories

- Galvanized Steel Pipe (151)

- Galvanized Steel Coil (103)

- Tinplate (22)

- Seamless Steel Pipe (142)

- Roofing Sheet (29)

- Square Steel Pipe (42)

- Angle Steel Bar (103)

- Deformed Steel Bar (68)

- PPGI Coil (29)

- Spiral Steel Pipe (14)

- Welded Pipe (36)

- Rectangular Steel Pipe (24)

- API Steel Pipe (15)

- Steel Sheet (32)

- Galvanized Aluminum Coil (15)

- Cold Roll Steel (20)

- Stainless Steel (20)

- Galvanized Steel Nails (27)

- Steel Wire Rope (29)

- Scaffolding Accessories (16)

- Prefabricated House / Steel... (8)

Type

- Carbon Structural Steel (65)

- Equal (162)

- Heavy (292)

- Light (141)

- Plate (140)

- Round (508)

- Spring Steel Bar (57)

- Steel Coil (71)

Grade

- 200 Series (16)

- 300 Series (38)

- 400 Series (87)

- HRB400 (240)

- Q195 (410)

- Q235B (569)

- Q345 (274)

- SS400 - SS490 (119)

Applications

- Boiler Plate (31)

- Construction (406)

- Container Plate (127)

- Manufacturing (621)

- Railway Rail (46)

- Steel Fabricated House (146)

- Steel Workshop (202)

- Structure Pipe (152)

News

Steel Coil Manufacturers Construct Anti-corrosive Coils to Work

Views: 384 Update Date: Feb 03 , 2016

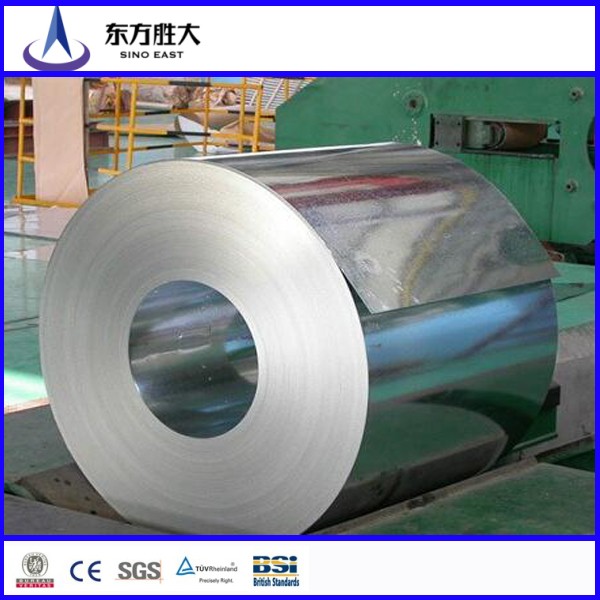

Manufacturers of steel coil make use of premium quality steels in grades including Q195, Q235, Q345B and SGCC in the construction of their products. They use galvanized steel for coil construction in order to make them anti-corrosive in nature. Steel coils are basically used as base material in the construction of different other equipments. Basically, it is used in construction industries to manufacture supportive products. In home appliance industry, steel coils are ideal to manufacture several home appliances. Apart from this, they are also ideal to use in automobile industry to produce various automotive equipments with strong structure.

The steel coil manufacturers treat the surface of cols used different materials such as chromic acid or oil and provide them with bright finishing to the customers. They make sure that their coils are spangle free and available with different weight values. Manufacturers use zinc for the coating of coils with excellent and shiny finishing. You can get each of the detail about coil on the website of the manufacturers. The thickness of the coil is depended on the requirement of the customers. The coils have capability to work in different environmental conditions with excellent tolerance and low density.

Apart from this, manufacturer offers you an affordable range of coils that you can paint in any color using good quality primers. The coils are also useful to manufacture sturdy roofing system with anti-rusting tendencies. In addition, you will be ensured by the professionals about proper packaging of your products. The coils are ideal to use in the area where there is extreme problem of corrosion. They are able to handle diverse temperature conditions efficiently and provide long lasting performance to the user Coils are thin sheets that are rolled up into the incessant coils using some well known processes.